Powering Indoor Farms Efficiently with Centralized Power

Indoor horticulture is growing in popularity as a reliable way of growing food that is not subject to the vagaries of the weather

Indoor horticulture relies on creating an environment for plants to grow with controlled heating, cooling and lighting – without relying on the sun – which require electrical energy.

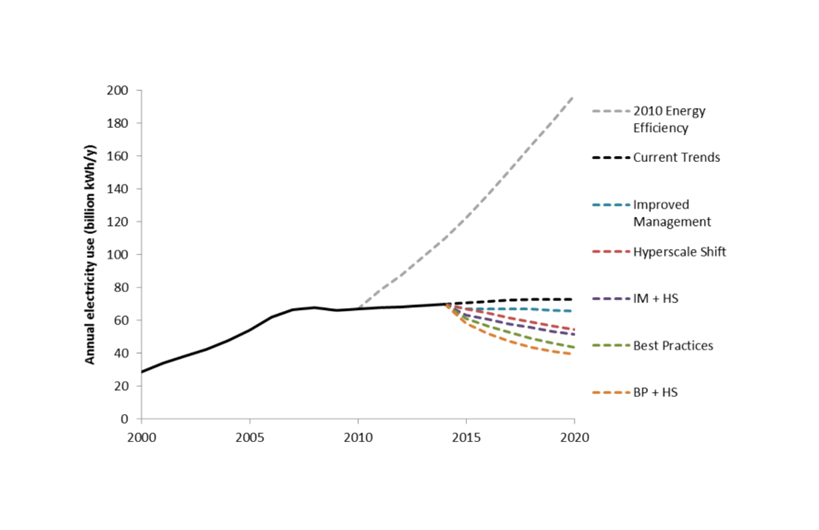

With rising energy costs and, in some areas, scarcity of supply, farmers are seeking systems that are reliable, controllable and affordable in terms of their capital and operating costs. In fact, the energy challenges faced in indoor horticulture is similar to those experienced in data centers. As data centers have bent the curve of their energy usage (figure 1) so too can solutions for efficient indoor farming.

Indoor horticulture or Controlled Environment Horticulture (CEA) is growing in importance as society’s attitudes adapt and change. Consumers are increasingly aware of the benefits of consuming fresh food. Growing locally also improves food security and reduces the impact of transport on the environment. As the growing environment is controlled, the season is extended and yields are improved.

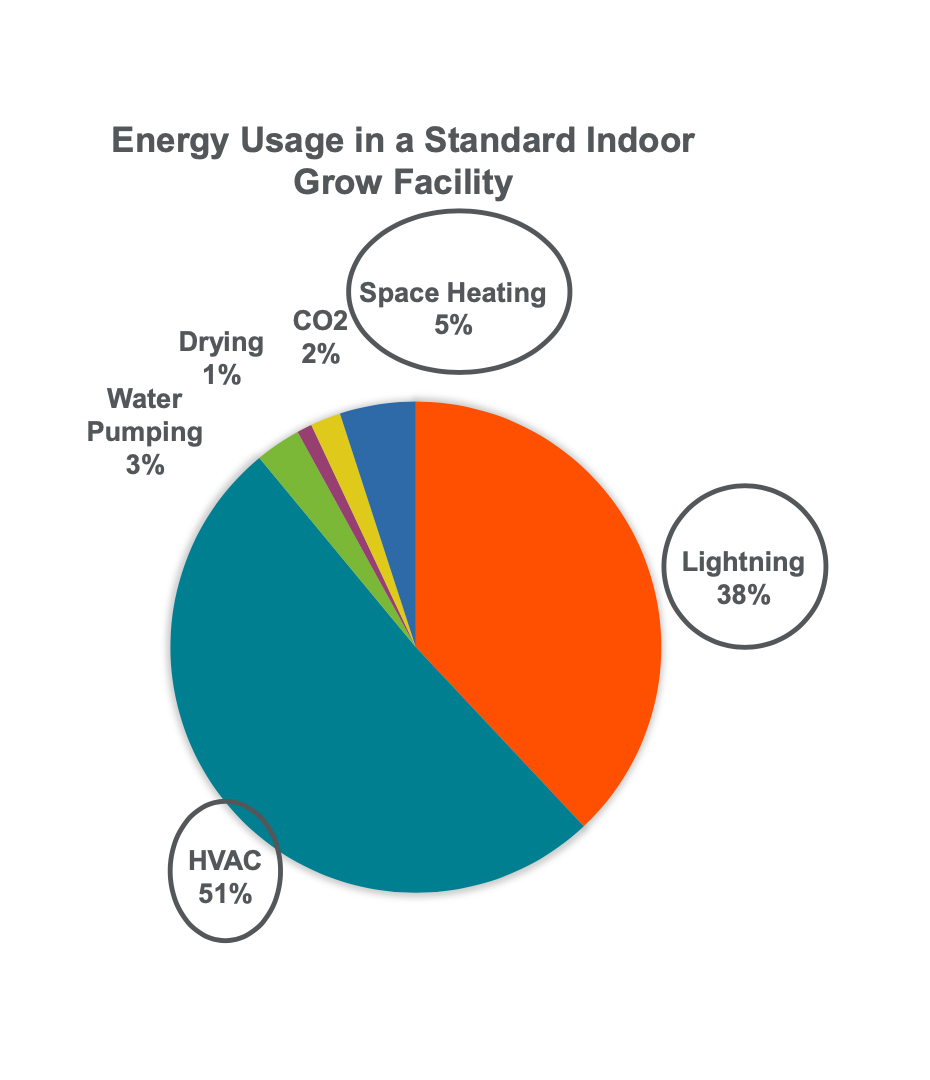

These benefits come at a cost. Providing the artificial environment requires a significant amount of electrical energy – primarily to provide HVAC and lighting. Together, these account for 94% of the energy usage in CEA (Figure 2).

Figure 2: Energy usage in a standard indoor grow facility

Figure 2: Energy usage in a standard indoor grow facility

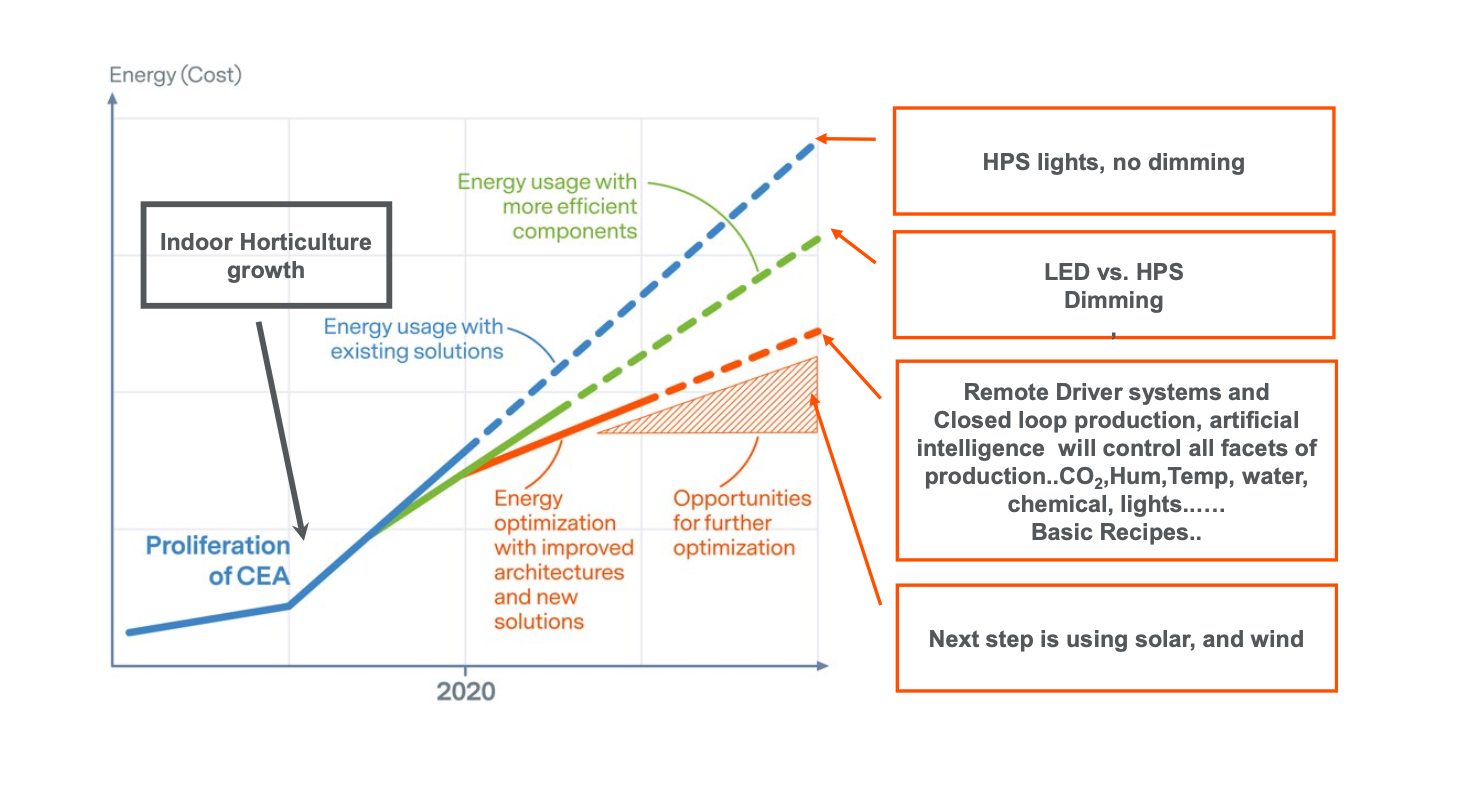

As indoor horticulture adoption expands, the energy consumed will also grow significantly – unless changes can be made to the components used, the power architecture and the source(s) of energy. The data center industry has faced the same challenge and, through a combination of technical changes and energy standards, made significant improvements (see figure 1)

Within CEA, the trajectory of the power curve can be improved by a number of steps: moving from HPS (high-pressure sodium) lighting to LEDs, introducing dimming for lighting, changing the power architecture and adopting renewable energy sources (see figure 3).

Figure 3: Ways to improve the power curve in CEA

Moving to LED Technology

The move from HPS lighting to LED seems obvious and is happening rapidly, but there is still further to go. Usage of LED lighting has grown approximately five-fold in the past six years as users recognize its benefits.

LED is more efficient, delivering more light-per-watt consumed and it has a lifetime that is at least four times greater than HPS lights. It is also capable of a much greater dimming range, allowing greater controllability in CEA applications. Even at the end of its life, LED is the preferred choice as it contains no mercury, unlike some HPS lighting, thereby eliminating the need for special handling and complicated recycling.

Adopting Remote Driver Architectures.

Moving to a remote driver architecture not only solves the challenges of getting the heat out of the grow area, but offers many other positive effects as we will see below.

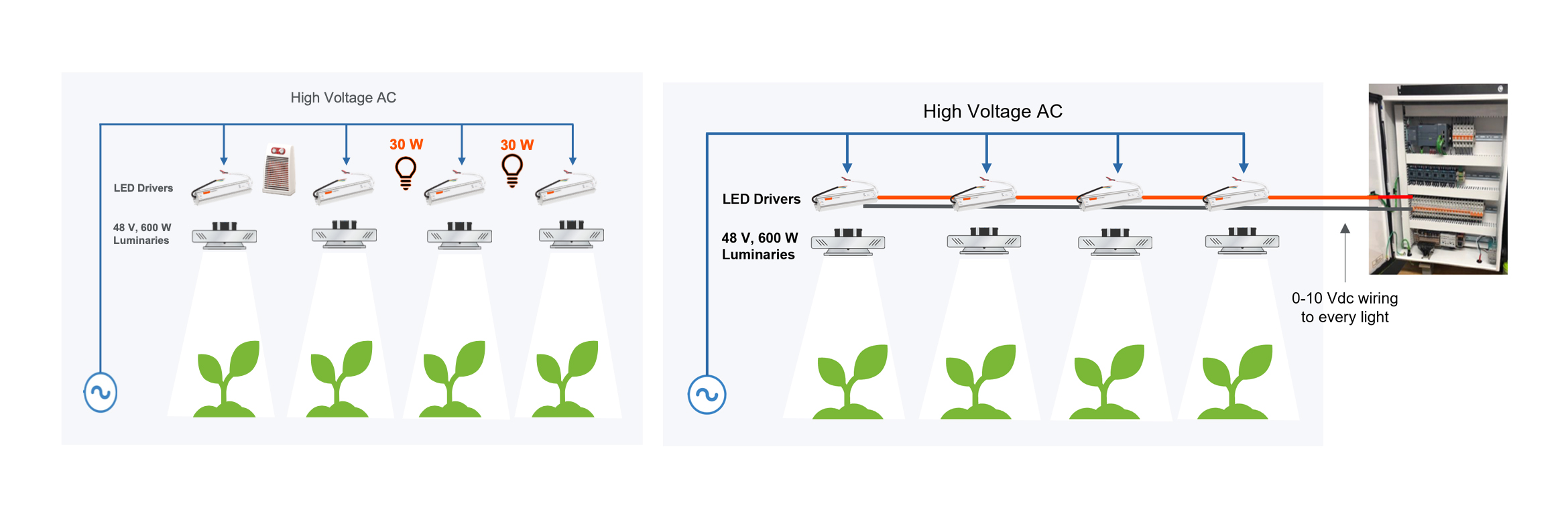

Figure 4a & 4b: Comparison of traditional power (4a) and remote architecture wiring (4b)

In a traditional approach (figure 4), each luminaire has its own driver located close by within the growing area. These types of drivers tend to have lower power factor (PF) and higher total harmonic distortion (THD), both of which increase energy costs. They also require a significant amount of wiring. Furthermore, there is a 3:1 ratio in the number of circuit breakers required. As power conversion is within the growing area, during warm seasons additional cooling is required to maintain an acceptable growing temperature.

Figure 5: Centralized Approach to LED Lighting

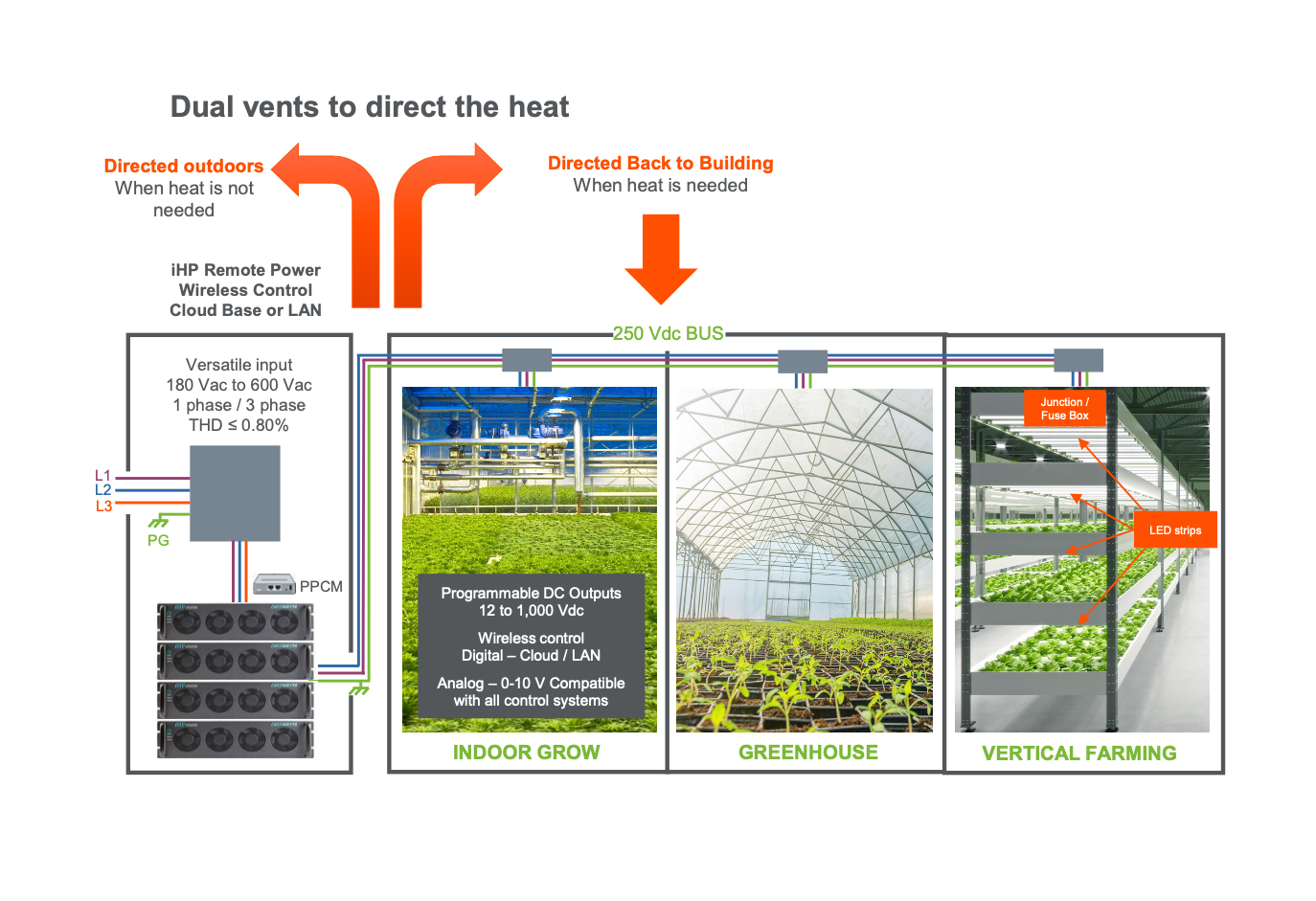

The challenges with the traditional approach can be overcome by changing to a high-voltage DC bus and moving the power conversion outside the growing area (Figure 5). Here, a single 3-phase PSU drives a 250 VDC bus, powering various types of LED luminaires.

This approach improves PF, THD and keeps the power line balanced, reducing energy costs and reducing the number of circuit breakers (reducing installation costs and system weight). Heat generated during conversion is outside the growing area and can be vented outside during warm seasons or vented into the growing area when it is cold – thereby reducing the energy needed for HVAC.

Optimized Technologies

Advanced Energy’s Artesyn™ LCM4000HV series 4 kW PSU and associated LCM12K mounting shelf has been designed specifically to provide a centralized current source for medium to large scale LED lighting within horticulture applications.

The unique input design can accept single- or 3-phase AC inputs from 208 VAC to 600 VAC. The output of each 4 kW block provides a flicker free current source at voltages between 100 VDC to 300 VDC and currents up to 16 A. The high voltage DC bus generated reduces the cost of wiring and power losses within the cable.

The convenient LCM12K 19” 1U rack mount shelf can contain three LCM4000HV modules delivering up to 12 kW. It is designed for hot plug replacement of the 4 kW modules, ensuring the simplest maintenance possible.

The associated intelligent transfer switch (iTS™) allows power to be switched to different loads, allowing a single LCM4000 rack to be used for multiple grow rooms, each requiring 12 hours of light per day.

Figure 6: Remote driver hardware

Figure 6: Remote driver hardware

Cost Savings From Central Drivers

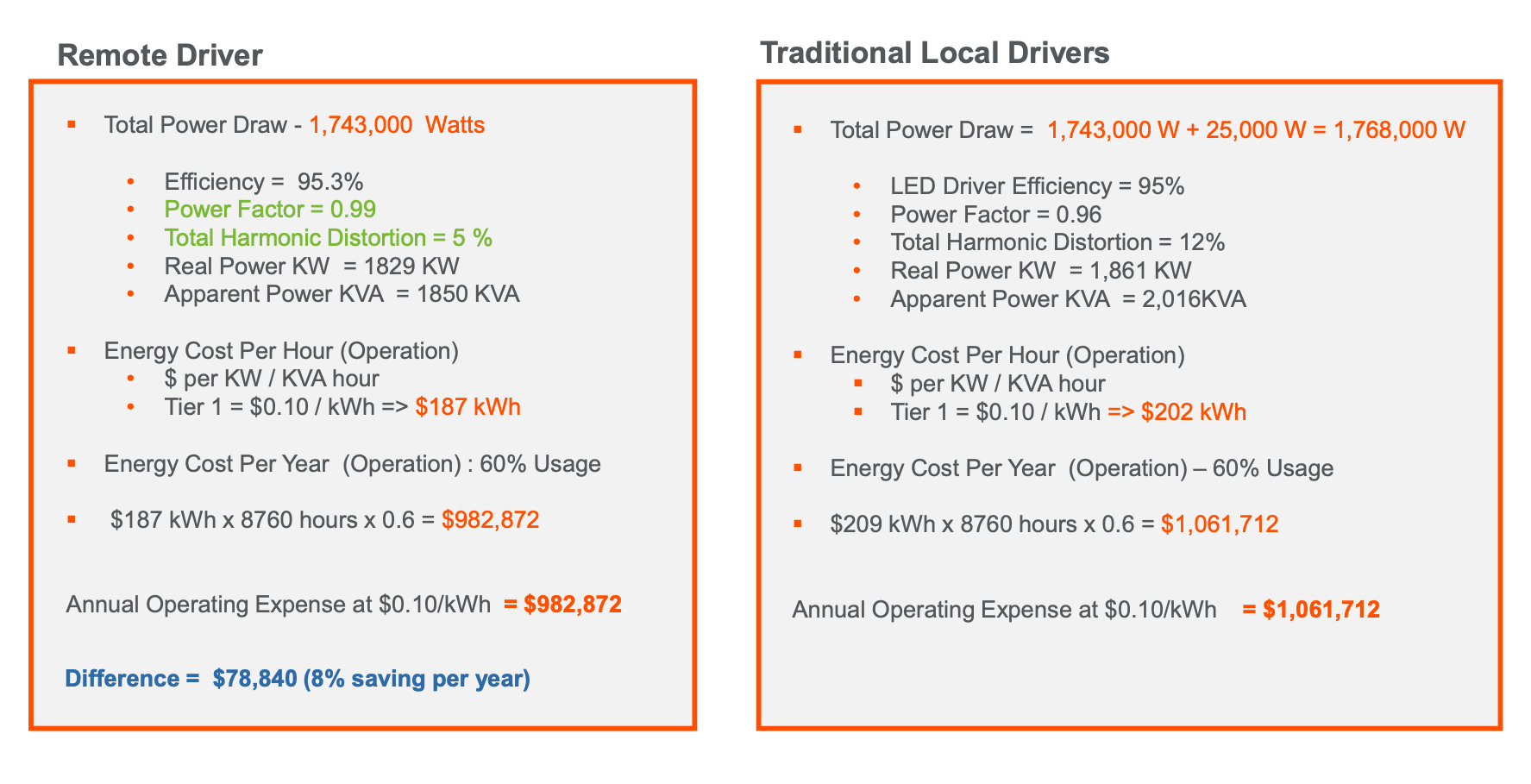

Consider a system with 1,743 1 kW LEDs operating for 60% of the time. Comparing local drivers with remote drivers, the approach illustrates the effects that poorer PF / THD has on OPEX.

Figure 7: OPEX comparison – conventional approach and centralized approach in a one-acre installation

The most significant difference is in the PF and THD, which is significantly better for the remote driver solution. This drives a significant difference in the apparent power, which is what energy bills are based on. Once the actual operating expenses are calculated, the remote driver solution delivers an OPEX saving of nearly $70k (6%) annually.

Additional CAPEX savings are available as the iTS transfer switch enables a single bank of PSUs to power two growing rooms. For example, the iTS can be programmed to power the first room for 12 hours and then the second, then repeat. Calculating the cost of the PSUs, iTS modules, controls and wiring for the remote driver approach and contrasting this with the cost of the drivers, controls, wiring and additional HVAC for the traditional approach shows a CAPEX saving of almost $169,135– or 39%.

In comparing two real-life installations, one for a 204,000 W facility and the other a 1,400,00 W facility it was assessed that the cost savings for just the wiring, circuit breakers and panels were 22% for the small grow and 49% for the large grow.

Summary

With indoor horticulture / CEA becoming more prevalent, there is a growing need to address the energy consumed in this sector and to reduce the installation costs. Moving to LED technology is beneficial in all configurations due to its longer life, greater efficiency and the absence of mercury which makes end-of-life disposal cheaper and easier.

Replacing the individual LED drivers with a single remote PSU located outside the growing area yields significant savings in terms of installation and running costs. Remote drivers are outside the growing area, so any heat generated by the PSU can be vented outside or indoors as needed.

Beside the utilities saving due to enhanced PF and THD there are many useful outcomes which include.

- Gets the heat out of the Grow Area

- Digital control – no dimming wires needed.

- Feedback into the health of the lights and driver.

- Reduced meantime to repair: easy hot swap of the failed driver and no climbing needed to replace drivers and lights.

- Lower utility costs thanks to the high-power factor.

- Reduced installation cost, including a 3-to-1 reduction in circuit breakers.

- A 4-to-1 lower shipping cost

- Reduced input current from utility mains to the grow facility with iTS.