Premises

Premises

In the era of Industry 4.0, the traditional methods of production and assembly lines have given way to a prevalence of robotic arms and mobile devices. Notably, Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) have taken on significant responsibilities in tasks such as cargo pickup and delivery. These vehicles, built in with central processing units (CPUs) and sensors, are adept at tackling more complicated tasks instead of repeating routines. In this article, we will discuss the structure and applications of AGVs and AMRs.

AGV & AMR – Innovation from original machines to smart vehicle

The evolution of these vehicles is closely linked with industrial advancements. The initial AGV was powered by cable and undertook heavy works like lifting and towing.

Subsequently, the advent of computers and sophisticated control technologies ushered in a new era, granting these vehicles heightened capability. They began to help humans to perform works in environments marked by intense radiation or fires.

In recent times, propelled by battery innovations, a fresh breed of AGV/AMR has emerged, powered by lithium-ion batteries. Infused with IoT devices and sensors, these vehicles establish internet connectivity, enabling them to execute tasks through seamless communication. This transformation has significantly elevated their operational smoothness and capabilities.

Power structure analysis

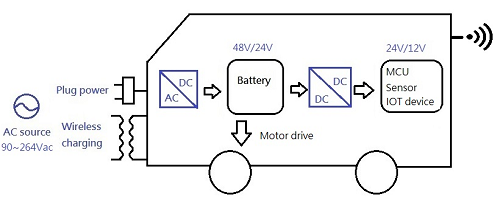

Let’s break down the power structure of a typical AGV/AMR:

At the core of the AGV’s power system lies the battery, serving as the primary source of DC power for its backend components. At the frontend, an AC/DC power supply featuring a management IC is responsible for charging the battery. The conventional way of recharging the battery involves a pad-touch charging station, while some innovative models have adopted wireless charging solutions to enhance mobility advantages.

Numerous widely used AGV/AMR models adopt battery voltages of 24V or 48V (achieved through two 24V units in series), which are then converted to 24V/12V for powering other end devices. In cases where the IC or MCU requires lower operating voltages, such as 5V or 3.3V, smaller DC/DC converters are essential to fulfill these requirements.

Real application case

1. Warehouse AGV Robot

The primary tasks of the warehouse AGV include lifting and supporting cargo boxes. Its battery operates at 48V (two units in series) and requires a DC/DC power converter to transform the voltage to 24V, providing 150W of power. Various components on the AGV, such as sensors and LEDs, demand a 12V power supply, hence necessitating the use of several smaller DC/DC converters to convert from 48V to 12V.

Image by macrovector on Freepik

2. Self-routing AMR /Robot

Various situations have witnessed the deployment of these autonomous AMRs with self-routing capabilities. These scenarios include services like delivery, informational interaction, and even advertising. Given the requirement to navigate around obstacles and self-route, these AMRs are equipped with sensors around the vehicle.

For powering CPUs or ICs, a smaller DC/DC converter becomes essential to transform the battery’s voltage (24V/48V) to levels like 5V or 3.3V, catering to the specific voltage demands.

Image by macrovector on Freepik

Cincon’s power solution for AGV &AMR

In the case of battery-powered mobile vehicles, the major voltage conversion requirements often focus on from 48V to 24V/12V or from 24V to 24V/12V. The nature of application scenarios, such as temperature variations, dust and humidity exposure, and vibrational conditions, results in diverse size constraints and working environments.

Cincon addresses these demands by offering robust DC/DC brick power solutions, ranging from 100W to 600W, meticulously designed for voltage conversion purposes. These brick powers offer several advantages:

1. The encapsulated design shields the unit from external water and dust.

2. Conduction cooling techniques support wide range of operating case temperature.

3. These modules are high power density and compact sizes, contributing to reduced overall weight and accommodation within limited spaces.

4. Most series are compliant to the Railway EN 50155 standard, demonstrating compliance with vibration and fire-related regulations.

For 48V input needs, Cincon provides both Chassis mount solutions (Filter built-in) and modules to choose.

| Model | Type | Wattage | Input Voltage | Output Voltage |

| CQB100W-110S | Quarter-brick module | 100W | 43~160V | 5V, 12V, 15V, 24V, 28V, 48V |

| CQB150W-110S | Quarter-brick module | 150W | 43~160V | 3.3V, 5V, 12V, 15V, 24V, 28V, 48V |

| CHB200W-110S | Half-brick module | 200W | 43~160V | 5V, 12V, 24V, 28V, 48V |

| CHB300W-110S | Half-brick module | 300W | 43~160V | 3.3V, 5V, 12V, 24V, 28V, 48V |

| CFB600W-110S | Full-brick module | 600W | 43~160V | 12V, 24V, 28V, 48V |

| CQB100W-110S CMFC(D) | Chassis mount | 100W | 43~160V | 5V, 12V, 15V, 24V, 28V, 48V |

| CQB150W-110S CMFC(D) | Chassis mount | 150W | 43~160V | 3.3V, 5V, 12V, 15V, 24V, 28V, 48V |

| CHB200W-110S CMFC(D) | Chassis mount | 200W | 43~160V | 5V, 12V, 24V, 28V, 48V |

| CHB300W-110S CMFC(D) | Chassis mount | 300W | 43~160V | 3.3V, 5V, 12V, 24V, 28V, 48V |

| CFB600W-110S CMFD | Chassis mount | 600W | 43~160V | 12V, 24V, 28V, 48V |

For input voltage covers both 48V/24V, Cincon offers module solutions as follows:

| Model | Type | Wattage | Input Voltage | Output Voltage |

| CQB50W8 | Quarter-brick module | 50W | 9~75V | 12V, 15V, 24V, 28V, 48V |

| CQE50W | Quarter-brick module | 50W | 18~75V; 9~36V | 3.3V, 5V, 12V, 15V, 24V, 48V |

| CQB75W8 | Quarter-brick module | 75W | 9~75V | 12V, 15V, 24V, 28V, 48V |

| CQB75W | Quarter-brick module | 75W | 18~75V; 9~36V | 3.3V, 5V, 12V, 15V, 24V |

| CHB75W | Half-brick module | 75W | 18~75V; 9~36V | 3.3V, 5V, 12V, 15V, 24V, 28V, 48V |

| CQB100W | Quarter-brick module | 100W | 9~36V; 18~75V | 3.3V, 5V, 12V, 15V, 24V |

| CQB150W | Quarter-brick module | 150W | 9~36V; 18~75V | 5V, 12V, 15V, 24V, 28V, 48V |

| CHB200W | Half-brick module | 200W | 10~36V; 18~75V | 3.3V, 5V, 12V, 15V, 24V, 28V, 48V |

| CHB300W | Half-brick module | 300W | 9~36V; 18~75V | 5V, 12V, 15V, 24V, 28V, 48V |

| CFB400W | Full-brick module | 400W | 9~36V; 18~75V | 5V, 12V, 24V, 28V, 48V |

Cincon provides a selection of models suitable for low-power converters under 10W for the needs of 48/24V inputs. (More suitable models in DIP/SMD 3-75W and SIP/SMD 1-10W)

| Model | Type | Wattage | Input Voltage | Output Voltage |

| EC3SAW | SIP8 | 3W | 18~75V, 9~36V | 3.3V, 5V, 12V, 15V, +/- 5V, +/- 12V, +/-15V |

| EC4SAW | SIP8 | 6W | 18~75V, 9~36V | 3.3V, 5V, 12V, 15V, +/- 5V, +/- 12V, +/-15V |

| EC5SAW | SIP8 | 10W | 18~75V, 9~36V | 3.3V, 5V, 12V, 15V, +/- 5V, +/- 12V, +/-15V |

| EC6AW | DIP24/SMD24 | 8W | 18~75V, 9~36V | 3.3V, 5V, 12V, 15V, +/- 5V, +/- 12V, +/-15V |

| EC7AW | DIP24 | 10W | 18~75V, 9~36V | 3.3V, 5V, 12V, 15V, +/- 12V, +/-15V |

There are more brick type DC/DC converters and low power converters that could meet the input voltage requirements. Please check Cincon DC/DC converter.

|

|